Dedicated Solutions

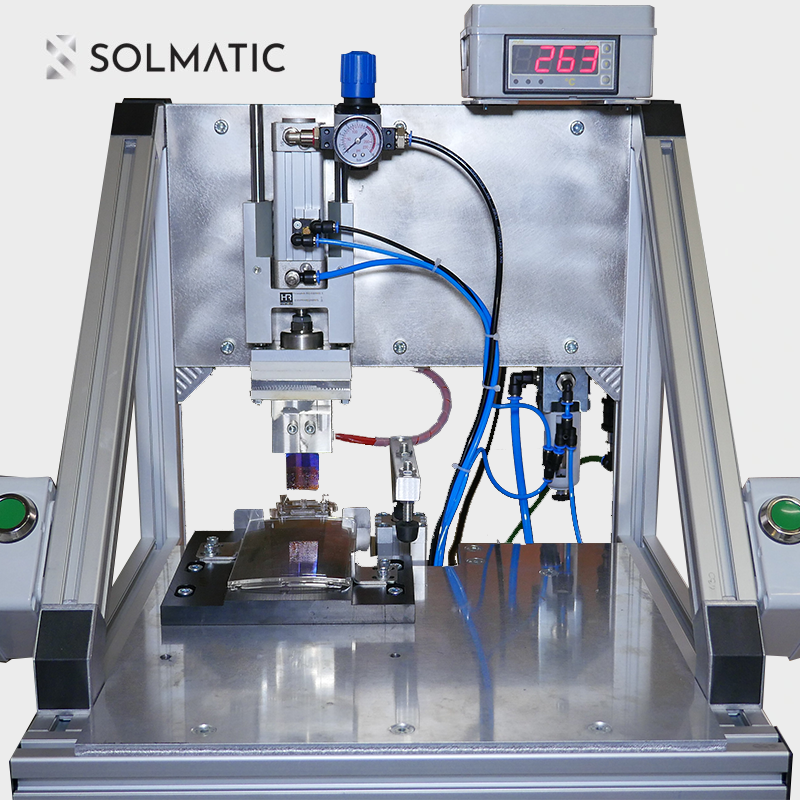

We deliver production machines made-to-order, providing a personalized proposal that fully meets customer expectations and maximizes the efficiency of the production process in the given plant. Additionally, besides designing and building entirely new production solutions, we introduce improvements and modifications to the machines that our clients already use, considering how demanding an investment in a new machine can be. Request a QuoteSolmatic Offer

Why Choose Us?

We start each project with a thorough analysis of the client’s needs. We offer fully customized solutions tailored to the specific production requirements and individual demands of the facility, ensuring maximum efficiency and process optimization.

All of our production machines are built using components from trusted, reputable suppliers. The high quality of the parts ensures reliability, long machine life, and minimizes service costs. By investing in the best materials, we ensure the stability and safety of our clients’ production processes.

We deliver solutions that not only increase efficiency but also optimize operational costs. With precisely designed systems, clients can reduce energy consumption, material usage, and minimize the need for operators, which directly translates into cost savings.

Our machines not only meet the latest technological standards but can also be integrated into existing production systems. This ensures that our solutions work seamlessly with already installed equipment, minimizing disruptions and maximizing production efficiency.