20 years of experience

Comprehensive Support • Individual ApproachWe provide comprehensive support at every stage of project execution – from analyzing the customer’s needs, through designing the machine, implementing it at the customer’s site, and training employees on its operation, even after the project is completed.

We focus on simplicity, intuitiveness, and reliability, which is why we have gained the trust of over 200 customers from more than 30 countries worldwide – both large and small companies – during our 20 years of operation. Request a Quote View Offer

How We Work

We Consult

We support our clients at every stage of the project, and long after it has been completed. We share our knowledge and experience, helping to optimize each production process to achieve maximum efficiency and productivity. Our experts not only provide advice on technical and maintenance issues but also on long-term machinery management strategies, ensuring reliable and trouble-free operation for many years.Our after-sales support goes far beyond simply responding to potential failures. We conduct comprehensive training for production teams to ensure that personnel are fully prepared to manage our machines effectively. We believe in building long-term relationships based on trust, and our mission is to give clients full control over production processes and the security of their operations.

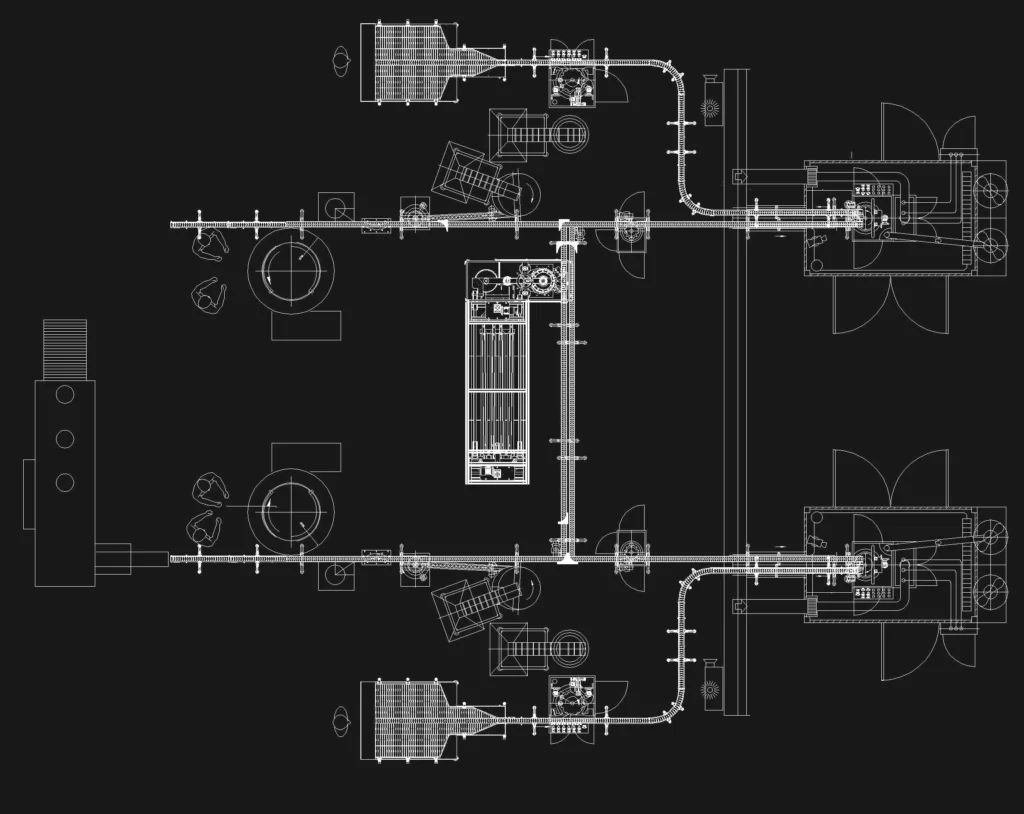

We Design

We create individually tailored solutions that not only meet current needs but also help our clients achieve their long-term business goals. Every project is carefully analyzed and adapted to the specific workplace challenges, taking into account its unique demands. With extensive experience and a team of skilled engineers, we deliver innovative and reliable solutions that streamline daily operations and deliver real benefits.

We Manufacture

Our production is based on extensive know-how, which allows us to provide the most advanced technological solutions. We have a qualified team of engineers and our own welding center and CNC machining facility, allowing us to fully control the quality of the most critical components. We use only proven materials and collaborate with renowned suppliers of automation and pneumatics components, ensuring the reliability and durability of our machines. With our experience and technology, we are able to deliver automated filling lines that meet the highest industry standards, such as the ATEX directive and Good Manufacturing Practices (GMP).We Startup

Before our machines reach the client, they are thoroughly tested to ensure full operational readiness. We begin the installation process with the confidence that all functions are working flawlessly. We want our clients to be fully focused on growing their business, so we offer full support during the startup of our machines.We train the client’s team to fully utilize the potential of our solutions, and we provide comprehensive user manuals. We also offer remote monitoring of machine performance and real-time technical support. Our goal is not only to ensure seamless production but also to enable clients to have full control over every stage of machine operation, no matter where they are located.

We Support

Our support doesn’t end with the startup of the machine. We provide comprehensive training for production teams, ensuring full operational readiness. If needed, we offer remote technical support, and we always have a stock of spare parts readily available to quickly meet our clients’ needs.Our goal is to ensure full satisfaction with our solutions. That’s why we maintain continuous communication with clients, answer any questions, help solve problems, and regularly provide software updates. Our long-term support guarantees that clients can rely on the dependable operation of our machines for many years.

Our Values

Reliability is the primary feature of our products. Along with it, we ensure stability and continuity of operations in the customer’s factory, minimizing production downtime and service costs, leading to increased process efficiency. In practice, this means full testing and quality control of every product before delivery, regular maintenance, and the implementation of a remote monitoring system. We also provide software updates and training for customers, contributing to the longer reliability of machines.

For us, integrity means transparency, clear agreements and transactions, fair pricing policies, and an individual approach to customers. We provide honest and clear information about products, respond quickly to problems, and deliver the highest quality customer service. We strive to build lasting relationships based on mutual respect, honesty, and satisfaction from successful projects. This gives our customers peace of mind and confidence that they can rely on our professionalism and focus on their business growth.

We operate with passion, which drives our innovation. We invest in research and the development of new technologies, collaborate with leading technical universities in Poland, refine projects, and support customer projects. Our passion for excellence and engineering drives us to deliver the most advanced and efficient solutions, driving progress in various industries. We constantly work on improving our projects to dynamically respond to the growing demands of the market and customers.

We adhere to the principle of open, clear, and effective communication. We respect our customers, business partners, and internal teams. We strive for mutual understanding and professionalism, actively listen to customer feedback, maintain regular contact, and provide training materials that help better understand our machines and fully utilize their potential. Our transparent communication builds trust and ensures that the collaboration process is smooth, efficient, and based on mutual respect.

Team

CEO

VP / Business Developer

COO / Export

tel: +48 533 376 773 PL / ENG

E-mail: j.poletek@solmatic.pl

Sales Manager / Parts & Service

tel: +48 668 218 842 PL / ENG / RUS

E-mail: s.ciupek@solmatic.pl