With a view of ensuring solutions of a top production quality to our customers as well as their safety (the pressure inside a container can reach levels of 6-10 bars!) we offer safe and proven systems for safety testing of aerosols. Tests are conducted by three types of machines: an automatic test bath, Gas leak detector and laboratory test bath.

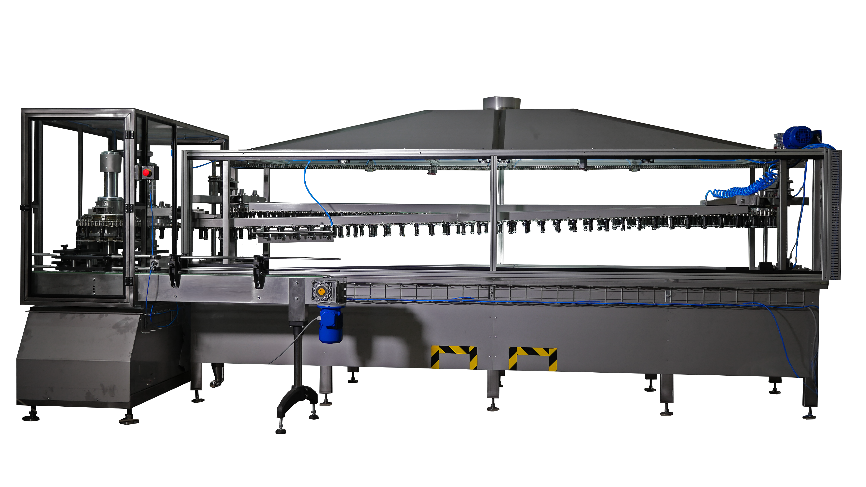

Automatic test bath

The use of constantly operating test baths is one of the most popular methods of testing the tightness of aerosol containers which have valves of specific sizes and types. The machine consists of a bath unit, drive unit, dryer and control panel and it does not require an additional person operating it. Let’s have a look at the operating scheme of the test bath. Aerosol cans filled with product move slowly through a water trough, they are immersed in the water of 60°C for 3 to 5 minutes. If any of the cans is leaking – it should explode at this stage. Leaking containers are taken from a production line. After leaving the water trough, containers are dried by a stream of high-pressure air. Solmatic offers three automatic baths each suited to production lines with different capacities. Every machine can conduct a safety test of 60, 80 or 120 containers per minute. Such system – even though proven and efficient – is rather energy-intensive. It requires heating 1000-1500 litres of water to a high temperature and its constant maintenance.

Gas leak detector

Aerosol producers are constantly in search of new, better ways of aerosol safety testing for leakages. Solmatic built an innovative machine as a part of an individual service for one of our Polish clients – a can leak detector (a gas sensors gate). The machine is used to detect a gas leak from aerosol cans which are on an existing technological line and to eliminate those faulty cans from further production stages. The gas sensors gate works with a transport conveyor where aerosol cans inspected by the gate move. Our machine is equipped with eight very sensitive sensors which inspect gas spectrum. How does the operating scheme of the detector look like in practice? Aerosol containers filled with gas are transported through two test stations. If the detector detects gas, it means that a can is leaking. A faulty can gets blown off the transport conveyor by compressed air nozzles and it falls into a ‘bin’ which is situated in the lower part of the machine, from where it is taken by an operator. The safety detector is a first device of this type created in Solmatic. It is our aim to constantly improve this technology in order to make it a cheaper and energy-efficient alternative to traditional methods of aerosol safety testing in the future.

Laboratory test bath

Laboratory test bath (manual) is an equivalent of the automatic bath, which conducts tests on a smaller scale. The machine is operated by one operator. How does this machine work? There is space for eight filled aerosol containers in the machine. An operator immerses tested containers in heated water by using a lever, thanks to this, it is possible to detect any leakages in tested containers by means of a visual check and to eliminate faulty items from a production line.

Which solution to pick up?

Everything depends on preferences, needs and possibilities of a customer. Solmatic offers solutions based on individual approach taking into consideration all current requirements of our customers, ensuring the comprehensive service and providing advice at every stage of the implementation of a project.