Offer Solmatic

- Throughput up to 100 units/min

- Precise sorting of valves with tubes and BOV and their transport to the filling line

- Designed for steel body valves with tubes and BOV

- Magnetic sorting system ensuring precise valve orientation

- Integrated sensor system and the ability to integrate with the valve elevator

Browse gallery

Watch video

Bayonet Gas Valve Sorter SFK-50

- Throughput up to 60 units/min

- Precise sorting of bayonet valves with an “L”-shaped tube

- Positioner and eliminator system ensuring precise valve orientation

- Smooth operation ensured by minimum/maximum sensors

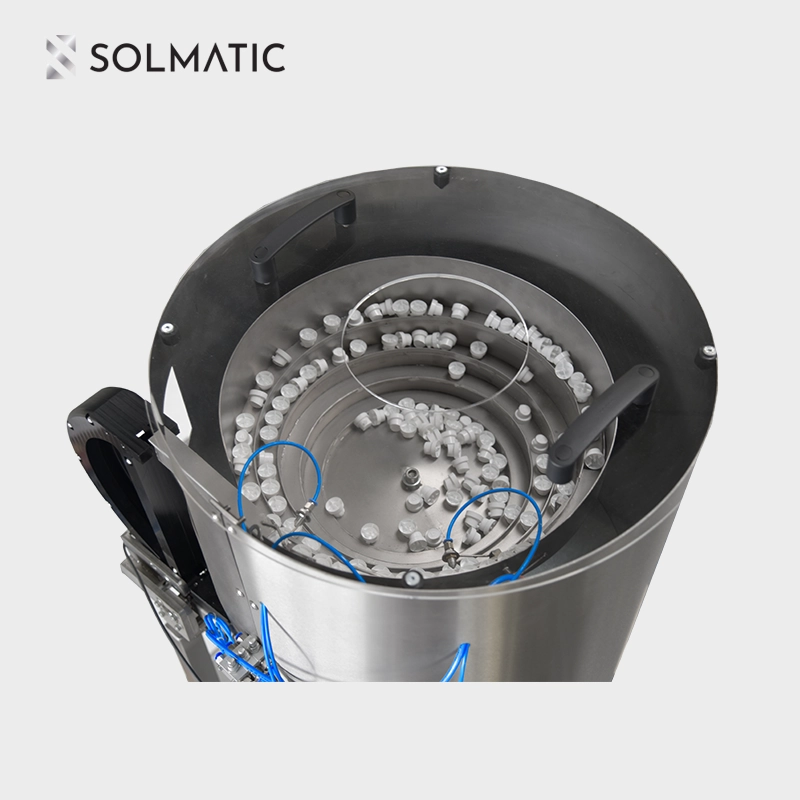

Magnetic PU and Threaded Gas Valve Sorter SOR-66

The Magnetic Valve Sorter SOR-66 is a device designed for the precise sorting and transport of threaded gas valves in aerosol filling lines. The device ensures a continuous sorting process, which is key to maintaining high production efficiency.

Valves are transported from the input reservoir through the sorting system and guides, then directed onto a chute where they are precisely oriented. The chute has minimum and maximum sensors that control the correct number of valves and ensure smooth operation. The valves are then transported to subsequent modules, such as Automatic Filling and Crimping Modules (AMR).

The magnetic sorting system ensures precise orientation of threaded gas valves, allowing them to be safely and accurately placed and subsequently crimped onto aerosol cans.

The SOR-66 sorter achieves a speed of over 60 units per minute, enabling fast and efficient valve sorting on any production line.

Key Features:

- 60 units/min throughput

- Precise sorting of threaded gas valves and PU valves

- Magnetic sorting system ensuring accurate valve orientation

- Smooth operation ensured by minimum/maximum sensors

Vibrating Sorters

- Capacity: 20-60 units/min, depending on project and type of elements

- Precise sorting of spray heads, applicators, valves, caps, atomizers, and other components

- Integrated sensor system: ensures the appropriate quantity of elements in the sorting basket

- Flexibility and versatility: customizable for different types of elements, including atomizers

Browse gallery

Universal Valve Sorter SZP-555

- Capacity up to 60 units/min

- Precise sorting of steel and aluminum valves with tubes and BOV

- Mechanical-gravity sorting mechanism

- Inclined sorting wheel with selecting blades

- Valve transport on a chute with pneumatic ejection

- Minimum/maximum sensor system monitoring the valve stock in the sorter’s basket

- Compatibility with Automatic Filling and Crimping Modules (AMR)

Cap Sorter SCZ-11

- Capacity up to 100 units/min

- Precise orientation of caps and delivery to the cap placer

- Sensor system automatically regulates the number of caps in the basket

- Interchangeable sorting wheel for different cap diameters

- Manually adjustable height with an option for automatic height adjustment

Browse gallery

Watch video

Cap Sorter SCD-218

- Speed of up to 300 units/min

- Precise orientation and transport of caps to the Highspeed Cap Placer OCS-217

- Modular sorting wheel with Click&Go™ technology for quick replacement

- Additional access flap for easier emptying of the sorter and faster changeover

- Manual height adjustment with the option for automatic height adjustment

- Minimum/maximum sensors on the cap conveyor ensuring smooth operation of the device

- Works in conjunction with the Highspeed Cap Placer OCS-217 for enhanced production efficiency

Why Choose Us?

You receive 100% personalized, tailored technological solutions, comprehensive service, and substantive support before, during, and after the project is completed.

By choosing proven, automated solutions, you increase efficiency, quality, and production speed, reducing the risk of production losses due to equipment faults and failures – thereby reducing costs. Solmatic automatic lines can fill up to 120 cans per minute.

Our machines are characterized by short changeover times, allowing you to maintain production process continuity and flexibility. With Solmatic equipment, you don't lose valuable time on machine changeovers – you produce more without generating unnecessary costs.

All Solmatic machines are covered by a warranty. We provide online warranty service, assisting our customers remotely regardless of their location. Our experts perform periodic inspections. We have a wide range of proven spare parts (if a part needs to be replaced during a technical inspection – we can perform this service immediately). Our representatives are present in the largest markets to respond to customer needs on an ongoing basis.