Cleaning-In-Place Stations

We are a manufacturer of modern systems for cleaning and disinfecting production lines. Cleaning-In-Place systems are a solution that increases profits while maintaining cleanliness in the production plant, where contamination in the form of production residues or bacteria is an inherent part. Request a QuoteHow does CIP technology work?

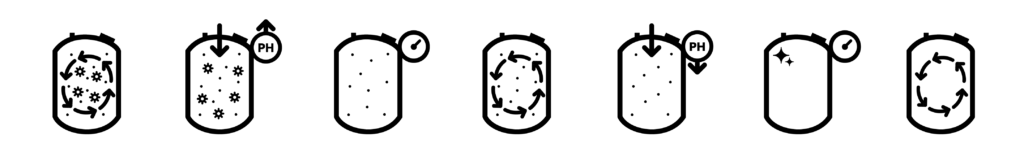

The CIP (Cleaning in Place) technology comes down to an automated, specially parameterized, and controlled cleaning process for the interiors of production equipment without the need for disassembly. This process uses precisely selected and applied chemical agents, temperature, and water flow to thoroughly clean the surfaces of tanks, pipes, and conveyors. CIP eliminates the need for manual cleaning, saving time and resources while meeting the highest hygiene standards in the food, pharmaceutical, and beverage industries.

Solmatic Offer

Why Choose Us?

Our CIP systems ensure the highest hygiene standards, essential in industries such as food, beverage, and pharmaceuticals. Regular cleaning of production lines eliminates contamination risks, preventing bacterial and harmful substance contamination. This not only helps avoid health issues but also prevents costly product recalls and potential fines for non-compliance with sanitary regulations.

Solmatic’s CIP stations allow production lines to be cleaned without halting operations. Continuous work without stoppages means increased profits and optimized production resources. This solution ensures higher efficiency and reduces the time-consuming nature of manual cleaning processes, allowing for sustained high operational productivity.

Our CIP systems provide complete control over every stage of cleaning production lines. Advanced sensors monitor key parameters such as pressure, temperature, and chemical concentrations, allowing for real-time process optimization. As a result, you achieve precise and repeatable cleaning, ensuring operational stability and eliminating the risk of errors.

Solmatic CIP stations help save resources such as water, chemicals, and energy. This not only lowers operational costs but also promotes eco-friendliness. Our solutions are designed to minimize raw material consumption, leading to long-term savings and sustainable development for your company.