Perfume Filling Machines

We produce perfume filling machines based on individual customer needs. We advise on the best personalized solutions, explain the application and possible uses and modifications of the machines, and also provide useful practices to increase production efficiency. Our devices can produce several dozen products per minute. Most of them feature functional components—interchangeable wheels or crimping heads that can work with valves of different diameters. Request a QuoteHow does perfume filling technology work?

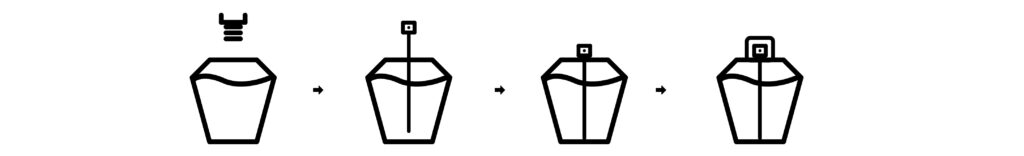

The perfume filling technology consists of precise liquid dosing into bottles, followed by the automatic placement of the atomizer, its crimping, and the pressing of the collar to stabilize the entire assembly. This process is fully automated and controlled, ensuring tightness and the correct dosage of the product. Perfume filling requires precision and adherence to high-quality standards to guarantee reliable application and the aesthetic appeal of the final product.

Ensure the safety and cleanliness of your production line with our modern CIP stations. See how they can further streamline and speed up changeover and production processes here.

Why Choose Us?

You receive 100% personalized, tailored technological solutions, comprehensive service, and substantive support before, during, and after the project is completed.

By choosing proven, automated solutions, you increase efficiency, quality, and production speed, reducing the risk of production losses due to equipment faults and failures – thereby reducing costs. Solmatic automatic lines can fill up to 120 cans per minute.

Our machines are characterized by short changeover times, allowing you to maintain production process continuity and flexibility. With Solmatic equipment, you don’t lose valuable time on machine changeovers – you produce more without generating unnecessary costs.

All Solmatic machines are covered by a warranty. We provide online warranty service, assisting our customers remotely regardless of their location. Our experts perform periodic inspections. We have a wide range of proven spare parts (if a part needs to be replaced during a technical inspection – we can perform this service immediately). Our representatives are present in the largest markets to respond to customer needs on an ongoing basis.