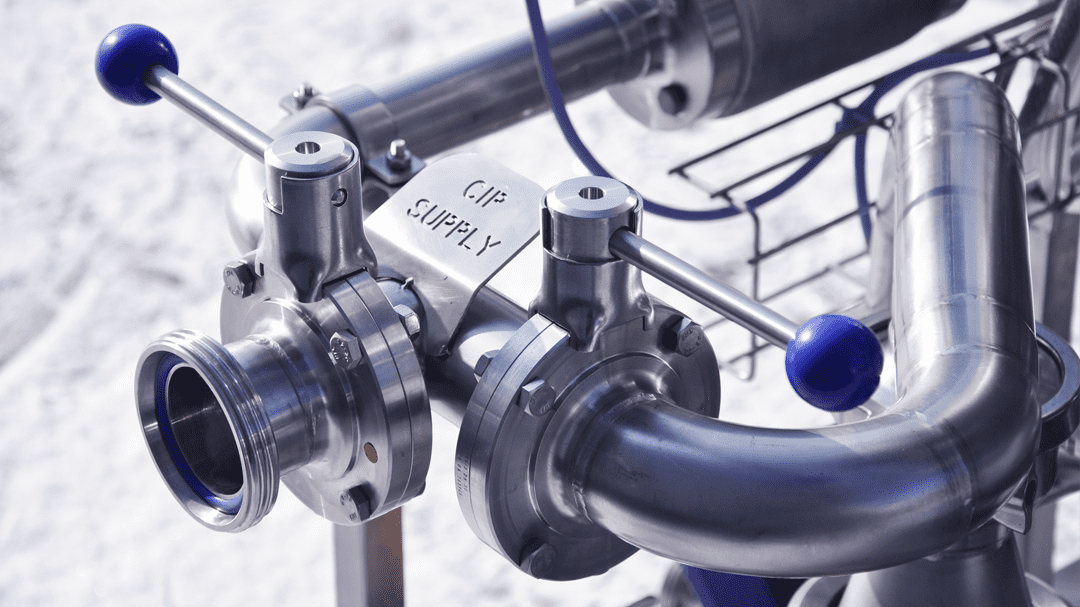

Modern Cleaning-In-Place systems make it possible to increase company profits and, at the same time, maintain cleanliness in production plants, where contamination in the form of production residues or bacteria is an inherent element. CIP stations guarantee the cleanliness of most parts of production lines: pipelines, filters, tanks, fittings and all other equipment that is exposed to the formation and deposition of contaminants.

Who are CIP systems for?

Cleaning-In-Place systems are suitable for industries where strict sanitary rules require the highest attention to hygiene and safety in the manufacture of products. They are therefore used in food processing, in the production of beverages and dairy products, during the manufacture of cosmetics and pharmaceuticals.

Advantages of Cleaning-In-Place systems

Cleaning stations allow equipment to be cleaned without prior disassembly, which significantly improves the efficiency of the production process and reduces labor input. Unclean production lines are prone to costly breakdowns (e.g. if filters are clogged by food particles, the entire production line will have to be shut down and serviced). Regular cleaning of production lines avoids machine breakdowns and high repair costs. In addition, CIP stations use economical solutions during operation - such as filtering several times or using the same water to clean the machines.

By using CIP systems, you can be sure to maintain the highest standards of hygiene in your company. Professional production line cleaning systems keep all equipment clean, preventing harmful bacteria and germs from getting into the products and food on the conveyor belt, thus guaranteeing high quality of manufactured products. The cleaning program itself (i.e. its pressure, time, flow rate or temperature) is fully adapted to individual needs.

Cleaning with a CIP station usually consists of the following steps:

- rinsing to remove residues,

- alkaline washing to remove fats and proteins,

- a second rinse with water,

- acid washing to remove mineral residues and neutralization,

- the final water rinse.

CIP station - mobile or stationary?

When you decide to implement Cleaning-In-Place in your company, you are faced with a choice: a stationary or a mobile station? Choose the type of station that fits in with your entire plant infrastructure and fully meets your needs in terms of functionality and comfort of use. The choice between mobile and stationary stations is determined by many factors - including the frequency of cleaning, the number of points to be cleaned, the location of the station and the diversity and structure of production. The financial factor cannot be overlooked. A mobile CIP station is suitable for plants with production lines located at several different points and where the plant requires a high degree of flexibility. In this case, the mobile station will not only be more economical for the plant, but will also be a good solution in terms of internal logistics. A stationary CIP station, on the other hand, will be a better solution for factories with rigid production line hours and short downtimes. Thanks to this solution, the plant will not experience losses connected with downtime, which would be generated by moving the mobile station from point to point.

If you are still wondering which type of CIP station will work best for your business, please contact our representatives - email: sales@solmatic.pl.

Why Solmatic?

We offer professional Cleaning-In-Place mobile and stationary stations, and an innovative washing machine for conveyor belts.

Our machines are made from proven components from reputable suppliers. The components - made of stainless-steel resistant to chemical and mechanical damage - ensure their durability and performance. Before we deliver a machine to a customer, we subject it to thorough performance and safety tests.

All our machines come with a warranty. We also provide an online warranty service to help you remotely, no matter where machines are. Our expert technicians carry out periodic inspections. We have a wide range of proven spare parts, so if a part needs replacing during a technical inspection, we can do it right away.

Every company has its own quality requirements and procedures. With this in mind, we attach great importance to creating tailor-made solutions. Our system allows you to configure the operation of the CIP station so that it fully meets the requirements of your plant. We are able to configure virtually all customer parameters - purity parameters (conductivity, PH, turbidity) can be measured and the cleaning process can be configured to stop only when specific values are reached.

Each Cleaning-In-Place station is equipped with an operator panel that graphically displays the entire cleaning process, so the operator can see in real time which stage of the cleaning process is active. The station collects all data on cleaning times and parameter measurements - which in turn can be saved in a format specified by the customer (e.g. in the station's memory, in the cloud or in a location specified by the customer).