Bag-On-Valve Machines

We deliver machines that enable the production of aerosols using Bag-On-Valve (BOV) technology, which aims to improve the quality of cosmetics, medical products, and food. By utilizing BOV technology, the product retains all its values, being separated from the propellant gas. Products filled using BOV technology can be dispensed up to 99% and can also be sprayed in any direction (even when holding the can upside down).

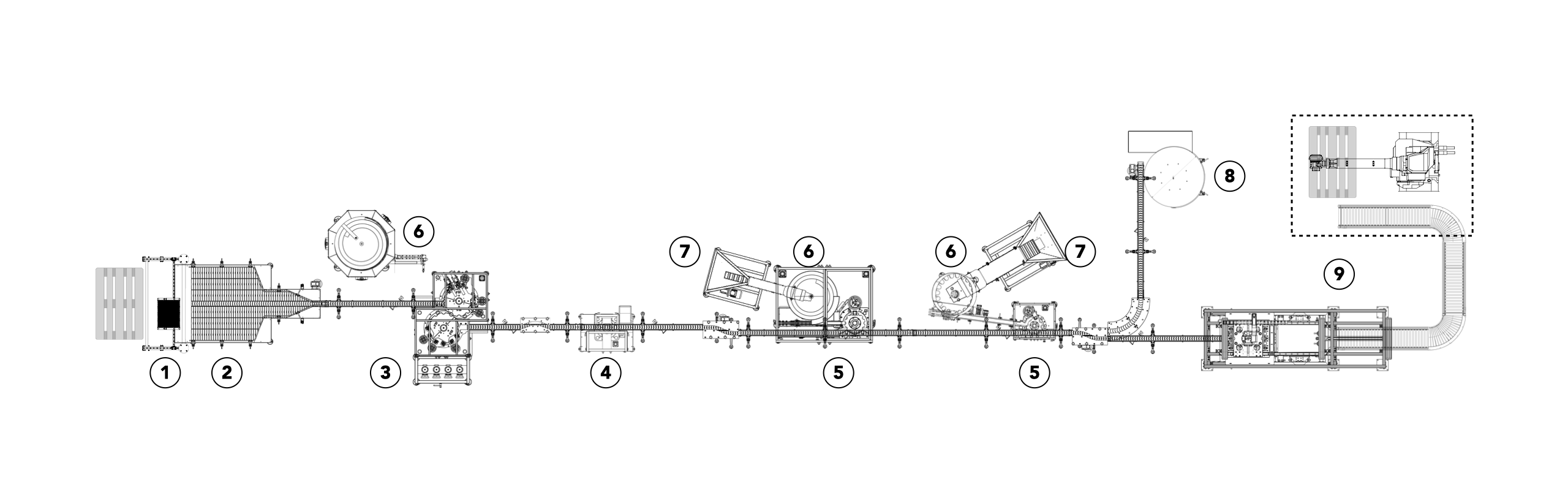

Most auxiliary machines used in aerosol filling lines can also be used in BOV lines, provided they are customized and adapted to industry regulations, including special materials.

Request a QuoteHow does BOV technology work?

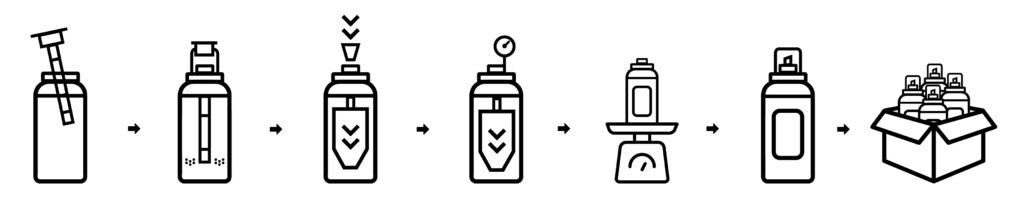

BOV (Bag-on-Valve) technology uses a special aerosol valve with a flexible bag inside. Gas, such as compressed air or nitrogen, fills the space between the bag and the container. The product inside the bag is dispensed by compressing the bag under the pressure of the gas when the dispenser is pressed. Unlike traditional aerosols, BOV does not use flammable propellant gases. This makes BOV technology safer and more environmentally friendly, benefiting both users and the environment.

Solmatic Offer

Ensure the safety and cleanliness of your production line with our modern CIP stations. See how they can further streamline and speed up changeover and production processes here.

Why Choose Us?

You receive 100% personalized, tailored technological solutions, comprehensive service, and substantive support before, during, and after the project is completed.

By choosing proven, automated solutions, you increase efficiency, quality, and production speed, reducing the risk of production losses due to equipment faults and failures – thereby reducing costs. Solmatic automatic lines can fill up to 120 cans per minute.

Our machines are characterized by short changeover times, allowing you to maintain production process continuity and flexibility. With Solmatic equipment, you don’t lose valuable time on machine changeovers – you produce more without generating unnecessary costs.

All Solmatic machines are covered by a warranty. We provide online warranty service, assisting our customers remotely regardless of their location. Our experts perform periodic inspections. We have a wide range of proven spare parts (if a part needs to be replaced during a technical inspection – we can perform this service immediately). Our representatives are present in the largest markets to respond to customer needs on an ongoing basis.